TRAPO innovations

are the engine of the automotive industry

As TRAPO GmbH, we counter the shortage of skilled workers and the highly competitive situation in the automotive and wheel industry with individual automation solutions. We relieve employees and provide them with cobots. Our team is quick on the draw, reacts to changes – and optimizes production lines. TRAPO expertise from 20 years of industry experience speaks for itself.

Our solution for your products

Tubes, wheels, tires or transmissions: TRAPO is a partner for production and logistics of various vehicle parts.

Product portfolio

Palletizing and depalletizing

We are proud of pioneering solutions in palletizing and depalletizing components.

See in actionPalletizing and depalletizing

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Flexible: omnidirectional movement of objects to the perfect position

With this considerable advantage, the HLP 6000 (HLP series) plays its unique selling point, absolute flexibility as a palletizing system: Because until now, a high level of modification was required to implement complex layer patterns. The HLP 6000 lays down perfectly and thus realizes any layer patterns of different formats.

See product

Load securing

Competent transport security for components of the supplier industry.

See in actionLoad securing

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Intermodal transport: securing pallets with wrappers

Companies in the automotive industry benefit from this film-saving wrapper: it also safely protects heavy, palletized goods for onward transport. Whether wheels or engine parts: they are secured fully-automatically by the TRAPO Stretch Wrapper (TSW series). In the process, the entire pallet is wrapped with film at high speed – this is how manufacturers ensure the required transport safety.

See product

Automated guided vehicles

Flexible transport of even heavy workpieces in the automotive industry.

See in actionAutomated guided vehicles

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Configure driverless shuttle with modular system

In the standard version, the TRAPO Transport Shuttle (TTS series) transports loads of up to 2.000 kg within production; higher loads are available on request. Sizes, energy transmission and storage as well as drive and navigation can be combined as required. In addition, there is the possibility of adding customer-specific superstructures, such as lifting function, conveyor systems or robots.

See product

Truck loading and unloading

You ensure safety on the road - we do in your loading zone.

See in actionTruck loading and unloading

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

One system loads several loading hatches autonomously

The TRAPO Loading System (TLS 3600) is a driverless, compact transport system with a lifting unit that can load three pallets simultaneously into a truck. In the process, it corrects its position automatically. This continuous loading process saves time and distance and enables the loading of a 13-meter-long semi-trailer with 33 pallets in about 15 minutes. The TLS can be moved and serves several loading hatches.

See product

Conveying systems

Engine blocks, wheels and more pass over our conveyor lines.

See in actionConveying systems

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Conveyor systems as standard for the automotive and wheel industry

In the field of conveying technology for the automotive and wheel industry, we have what is probably a unique product breadth and depth. Use this knowledge for your production – no matter whether you want to move wheels, rims, brake hoses, heavy engine parts or sensitive molded parts. Rigid, proven components are just as much a part of the range as mobile conveyor lines. Made in Germany – the entire portfolio of conveyor systems is manufactured at our headquarters in Gescher-Hochmoor.

See product

Transport standing wheels

Pioneering solutions from TRAPO GmbH are state of the art today.

See in actionTransport standing wheels

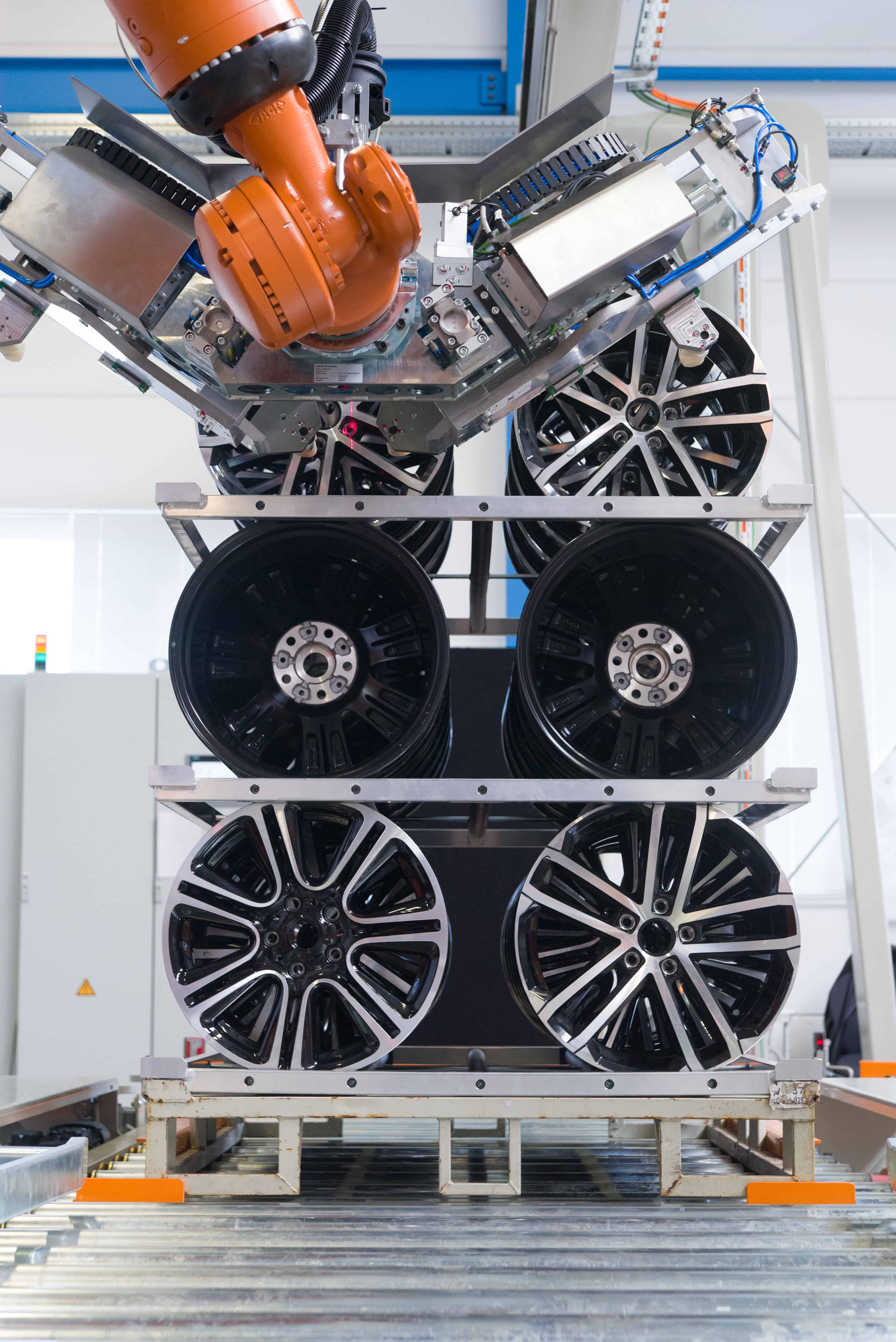

TRAPO USP: Transport of gloss-turned sports wheels

In production, light alloy wheels are first painted black, then part of the paint and material is removed; this creates the gloss-turned wheel, which is finally protected with an additional clear coat and must be kept absolutely clean during this process. As a pioneer, the development team at TRAPO GmbH took on the special challenge of safely depalletizing both horizontally and vertically palletized wheels with one system.

See product

Cobots

As assistance robots, they take on a supporting role in the truest sense of the word.

See in actionCobots

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Smart robotics for “colleague” robots

The design of cooperation between man and machine is firmly anchored in TRAPO GmbH’s mission statement, in order to humanize workplaces in the automotive industry and achieve production processes of consistently high quality. Cobots are equipped, according to their task, with multifunctional, individual robot grippers. They provide support as stationary jointed-arm robots, can be moved on rails or achieve maximum mobility – when placed on a driverless transport system from the TTS series.

See product

Automotive Industry 4.0

Data management for transparent manufacturing processes and optimization.

See in actionAutomotive Industry 4.0

Automation and control of the plants

Numerous innovations from TRAPO have been the driving force behind this industry. With TIM, the TRAPO Intelligent Management System, we have taken on the important task of centrally controlling, monitoring and optimizing processes in production and intralogistics. Because from now on, all those involved in the process have relevant figures in view 24/7.

See product