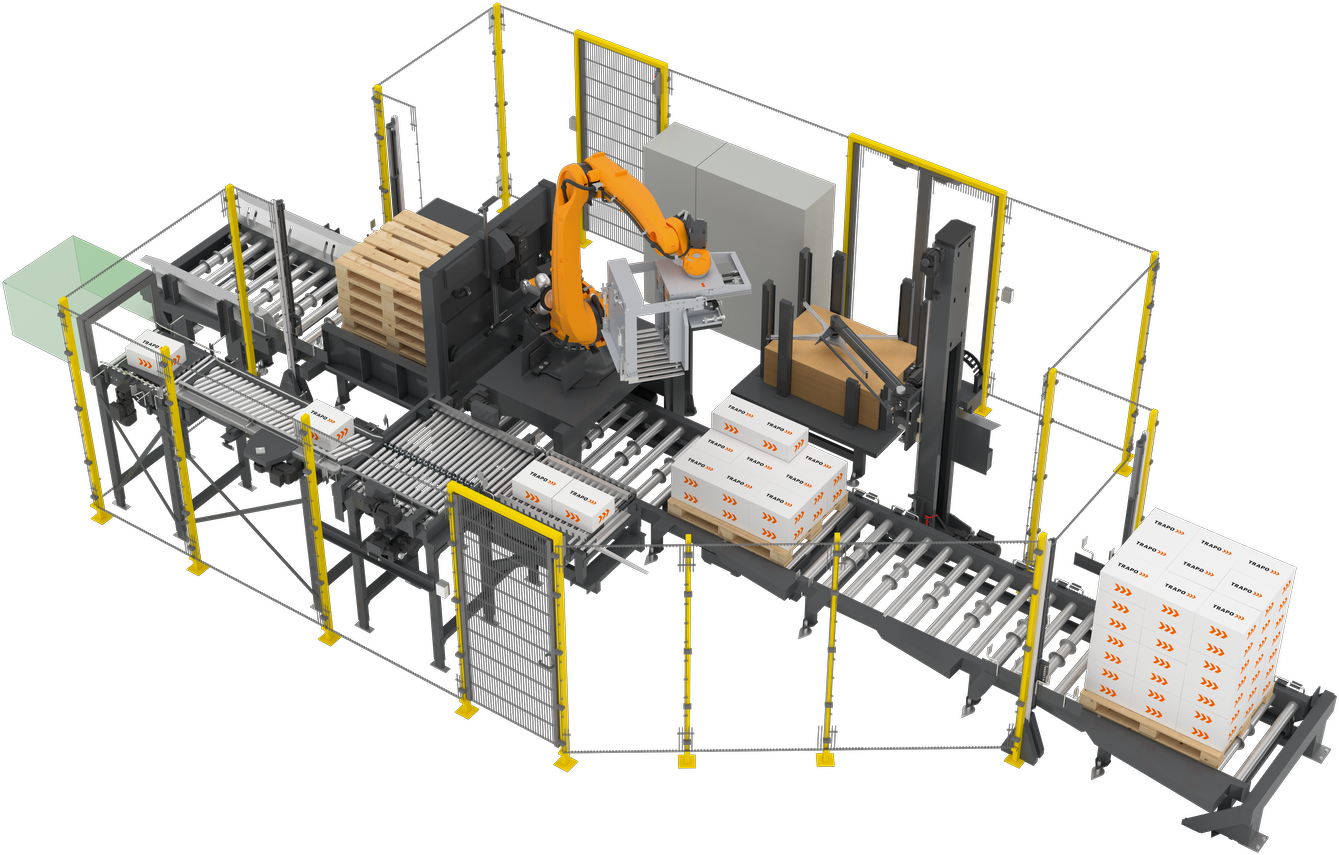

The Innovative TRAPO Palletizing Robot: Precise and Efficient Palletizing on Euro or Industrial Pallets

The TRAPO robot palletizer sets standards in product handling and productivity to optimize your manufacturing process.

Palletizing, numerous possibilities: Our innovative solution offers a variety of articulated robots and grippers to meet individual requirements.

Reliable Conveyor Technology

The entire process is supported by a reliable roller conveyor. This ensures not only a smooth feed of products but also an organized provision of pallets. Optionally, the supply of empty pallets can be done through a special empty pallet magazine to further optimize the workflow.

Optional: Interlayer Handling

The flexibility of our robot palletizing cell is enhanced by optional interlayer handling. This can be integrated as an additional function of the robot palletizer or implemented through a standalone interlayer handling with interlayer magazine. This function enables precise and efficient interim storage of your products for optimized handling and transport.

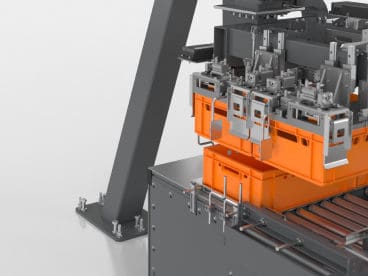

The High-Speed Robot System Introduces Itself in Two Variants:

The TRAPO HRS in the U-Line version functions as an independent palletizing cell and can be installed in any production environment. The arrangement of loading and unloading conveyors on one side ensures short distances and smooth pallet handling.

The TRAPO HRS in the Inline version is the preferred choice when the palletizing robot needs to be integrated into existing conveyor technology.

The Palletizing Robot in Action

Advantages at a Glance

Custom Grippers – Perfectly Tailored to Your Product

Precise handling of objects is a central challenge for robotic systems. To meet this requirement, the TRAPO Technology Center develops and tests gripper techniques precisely tailored to the specific characteristics of the objects.

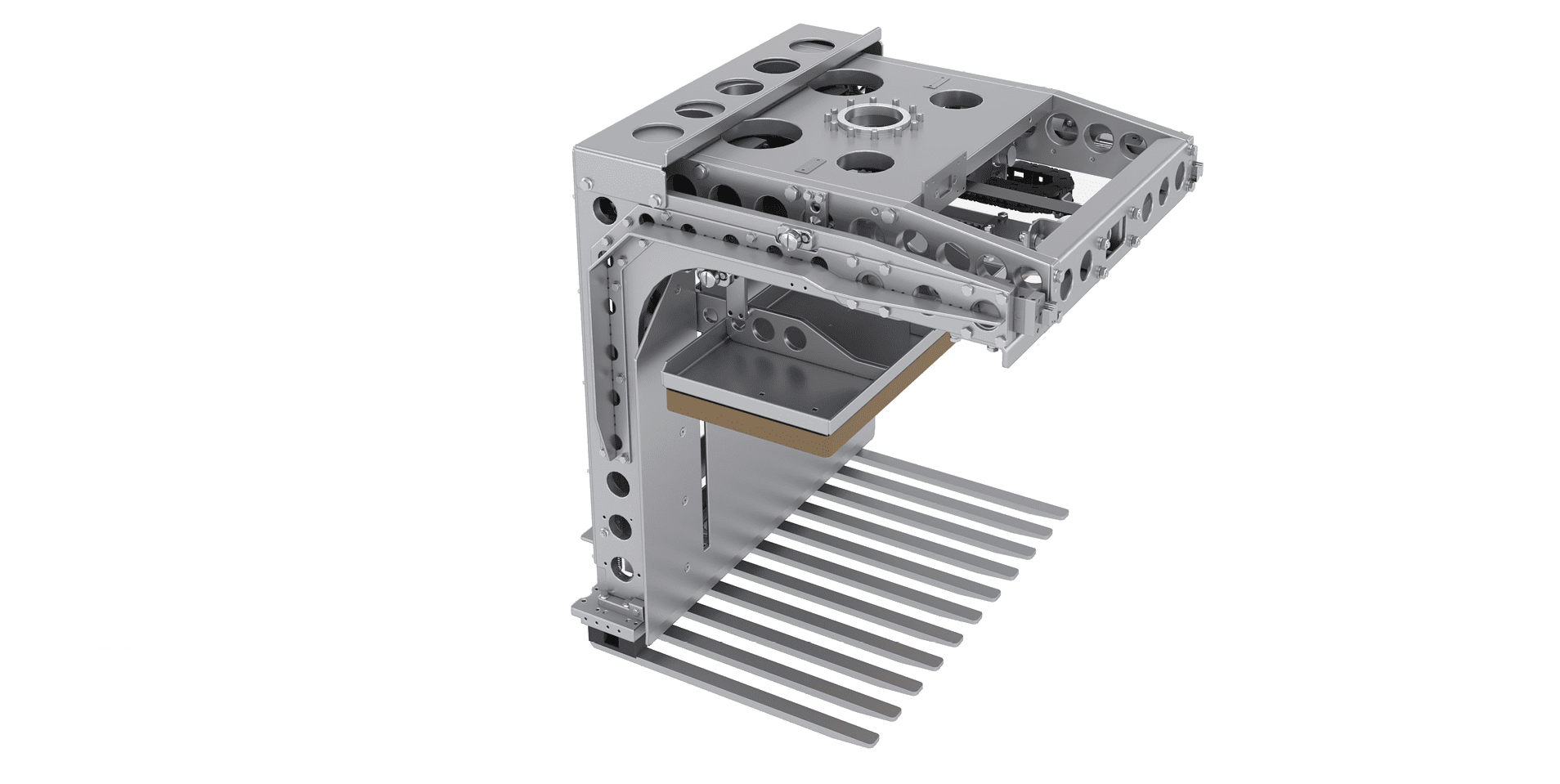

Fork Gripper

Retractable fork grippers are suitable for handling cartons, open containers, or bags.

The design of the fork gripper allows the products to be picked up directly from the roller conveyor on their underside.

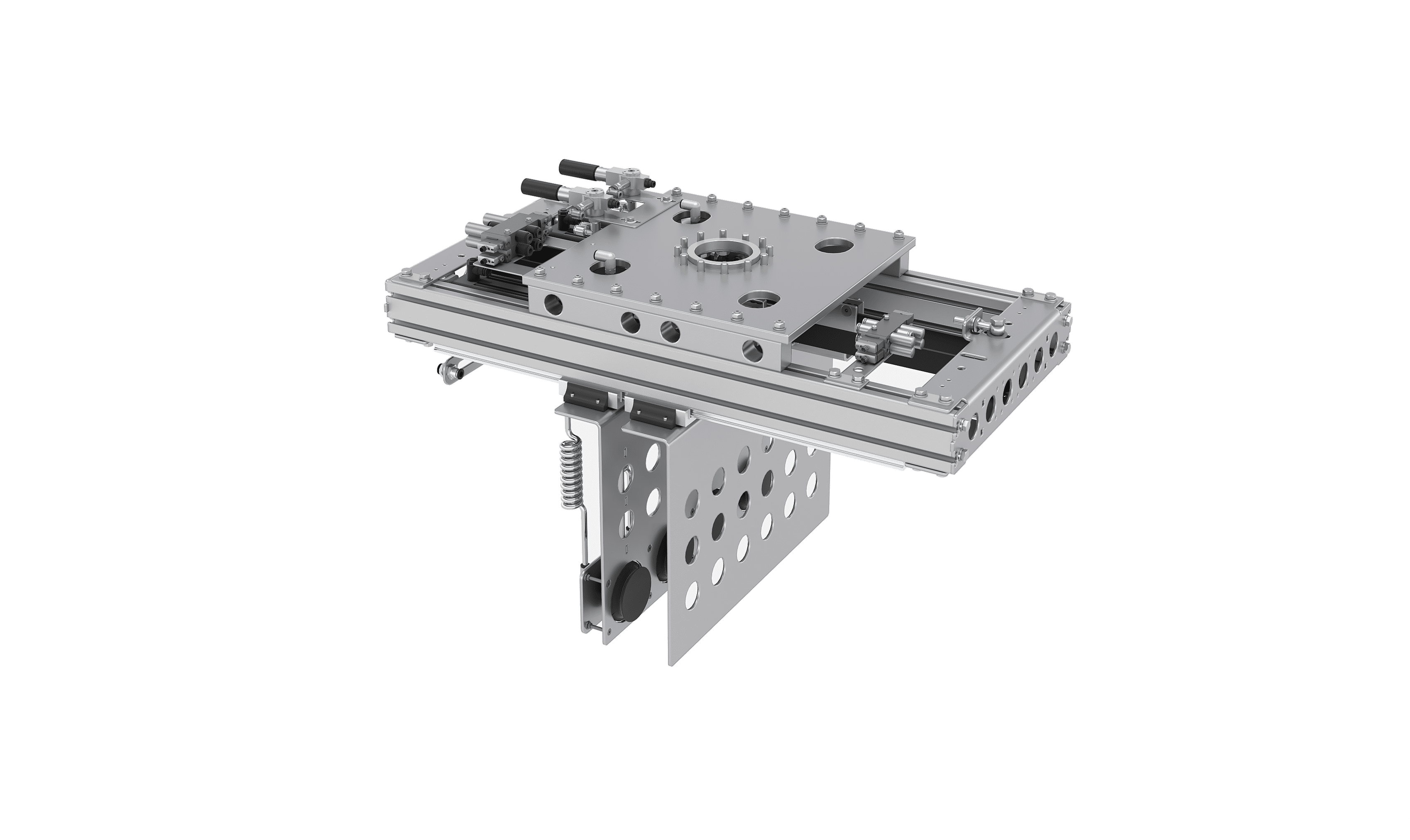

Clamp Gripper

Clamp grippers are suitable when products cannot be suctioned and are characterized by their reliable and gentle grip on the products.

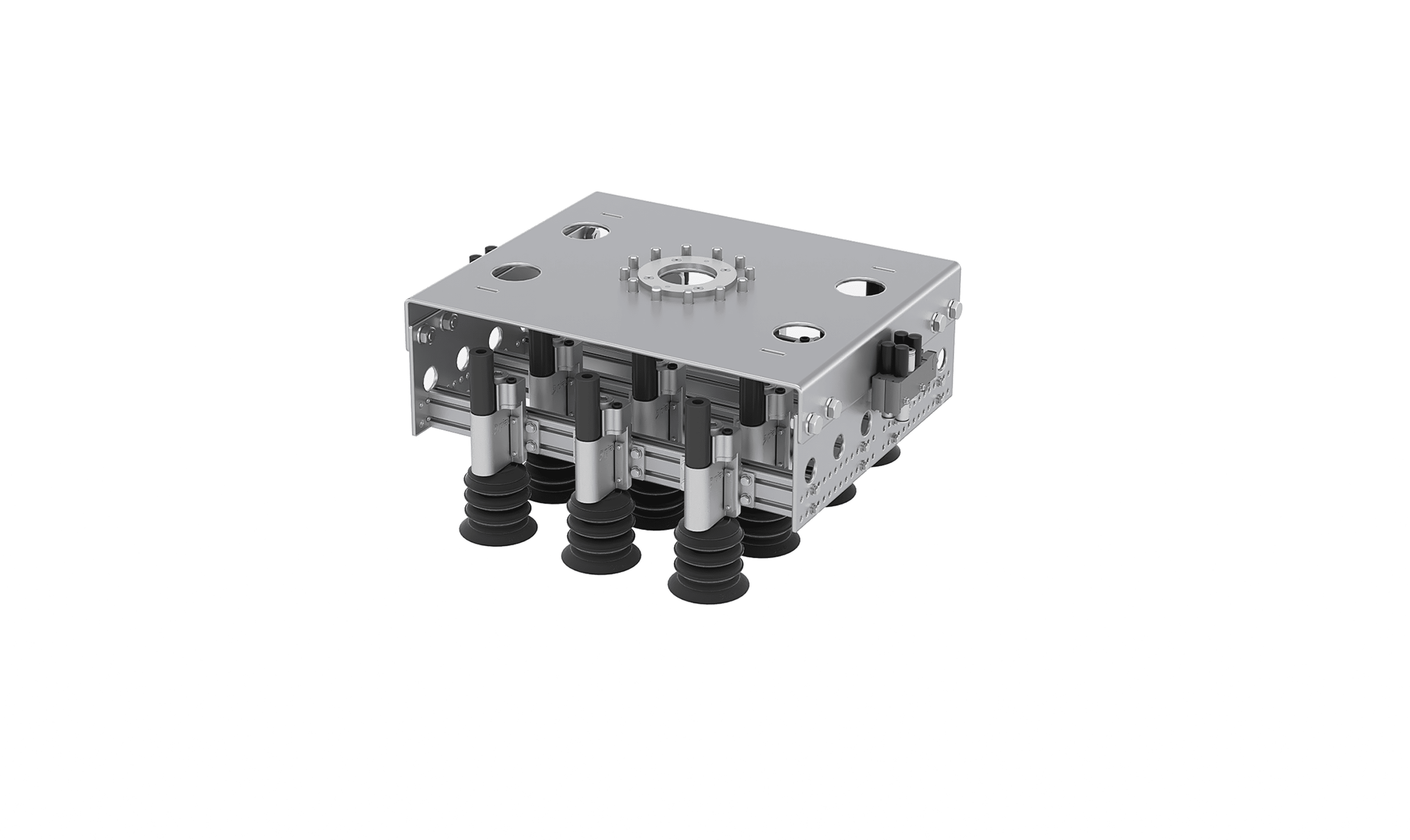

Suction Gripper

Smooth and airtight products are securely picked up and transported by suction grippers.

Facts and figures

HRS U-Line:

Length: 10133 mm

Width: 5816 mm

Height: 4100 mm

HRS Inline:

Length: 11760 mm

Width: 5800 mm

Height: 4100 mm

Höhe: 4100 mm

Description

Full pallet (Euro format)

Full pallet (industrial format)

Intermediate layers

Cardboard boxes

Dimensions (mm)

1200x1000x2000

1200x800x2000

min. 1000×700

min. 120x90x100

max. 500x400x400

Weight

1500 kg

1500 kg

max. 3 kg

max. 15 kg

Other

suitable for roller table

suitable for roller table

suckable

Description

Robot

Robot

Gripper

Gripper

Gripper

Option: Pallet magazine

Option: Intermediate layer handling

Option: Active product rotation

Option: Grouping

Variants

KUKA

ABB

Suction gripper

Clamping gripper

Fork gripper

Roller conveyor with magazine

Lifting rotary axis and gripper

Note

Load capacity depends on product

Load capacity depends on product

Max. Load capacity: 40 kg

for Euro and industrial format

Alternative to suction cups on the main gripper

max. 15 kg

Pusher for product conveyor technology