We optimize the gentle production of food-grade pet food

For pet owners, dogs, cats etc., are real family members. They are optimally and variedly supplied with food-quality pet food. In the case of canned food, we provide support with a high-performance layer depalletizer operating at ground level, which makes up to 90,000 cans available for filling every hour. Because not only the feed, but also the production should be of the highest quality.

Our solution for your product

TRAPO solutions take responsibility in sensitive animal feed production: from A for automation to Z for central warehouse.

Product portfolio

Pick and Place

Large working radius, repeatability and precision: picking food.

See in actionPick and Place

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Pick and Place solutions for the Pet Food Industry

From daily rations to reward treats, primary packaged products in the pet food industry are safely picked to order under high speed by TRAPO applications.

See product

Mixed tray formation

Pick food and combine them into mixed trays.

See in actionMixed tray formation

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Mixing trays: automated solutions provide variety with system

In order to make it easy for the consumer and animal lover – and tasty for the pet, pet food is offered in the trade in mixing trays. It is the task of the TRAPO application to depalletize unmixed containers and to combine them into mixing tray combinations according to the manufacturer’s specifications.

See product

Palletizer

Extremely compact on several levels

acting: high-performance layer palletizer.

Palletizer

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

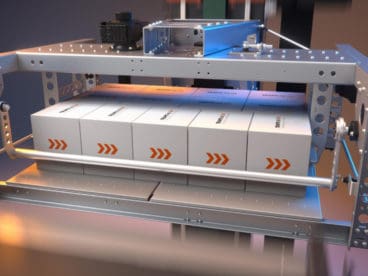

Gentle and efficient: palletizing feed cartons at 10 layers per minute

With the high-performance layer palletizer HLP 6000 from the HLP series, TRAPO provides the feed industry with an all-rounder: The exact layer formation – here with parallel kinematics – lays the safe foundation for the transport and the undamaged arrival of the feed at its destination. The HLP 6000 can produce up to ten layers per minute.

See product

Depalletizer

Ground level depalletizing line: 90,000 empty cans or jars per hour.

See in actionDepalletizer

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Unique in the world: ground-level can depalletizing

This TRAPO solution makes everyday work in pet food production easier – for food-grade pet food. The high-performance layer depalletizer offers two innovations: ground-level operation and a depalletizing capacity of 90,000 empty cans per hour.

See product

Load securing

Wrapper for securing pallets with food products.

See in actionLoad securing

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

TRAPO wrapper secures palletized animal feed in different containers

The TRAPO Stretch Wrapper (TSW series) creates the basic conditions for palletized transport of animal feed with fully automatic securing. At high speed, the entire pallet is wrapped with film – this is how manufacturers ensure the necessary transport safety.

See product

Automated guided vehicles

Mobile conveyor technology made of stainless steel for flexible, effective use of space.

See in actionAutomated guided vehicles

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Of the benefits Driverless shuttles for transport routes in the pet food industry

TRAPO enables multiple space benefits through the use of shuttle fleets – by eliminating rigid conveyor lines. As standard, the TRAPO Transport Shuttle (TTS series) transports loads up to 2.000 kg within the production area, higher loads on request. In addition, there is the possibility of adding customer-specific superstructures, such as lifting function, conveyor systems or robots.

See product

Warehousing

Storage and retrieval of goods with limited shelf life in (high) rack storage.

See in actionWarehousing

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

TRAPO competence: Safely storing and retrieving pet food in the (high-bay) warehouse

At the high-bay warehouse, one or more TRAPO Warehouse Shuttles (TWS series) accept animal food containers as required. The TWS accelerates at 1.5 m/s² and completes the cycle of extending, gripping and retracting in a maximum of three seconds. The rack system has a modular design and can be flexibly expanded. Consequently, performance can be significantly increased at any time by adding additional TWS and additive lifting devices.

See product

Autonomous loading and unloading

Fast and safe truck and container loading of palletized goods.

See in actionAutonomous loading and unloading

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Efficient loading and unloading: One system serves several loading bays

Safe is safe: The TRAPO Loading System (TLS 3600) is a driverless, compact transport system with a lifting unit that can always load three pallets of feed into a truck in parallel – replacing accident-prone forklift traffic. At the ramp, it corrects its position automatically. This continuous, autonomous loading process saves time and distance. The TLS can be moved – and reliably serves several loading hatches.

See product

Conveyor technology for care areas

Customized conveyor technology for the pet food industry.

See in actionConveyor technology for care areas

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

TRAPO optimizes conveyor line

From individual elements to complete conveyor systems: we optimize the flow of materials – taking into account the special requirements of animal feed production. TRAPO GmbH wrote the first chapter of its success story with conveyor technology. Today, rigid, proven components are just as much a part of the product range as mobile conveyor lines. Made in Germany – the entire portfolio of conveyor systems is manufactured at the headquarters in Gescher-Hochmoor – also in stainless steel on request.

See product

Cobots

Cobots for consistently high efficiency and low risk of injury.

See in actionCobots

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Smart robotics for “colleague” robot

Sometimes two hands are not enough for a task in the pet food industry – in that case, cobots with individual robot grippers lighten the load. The design of the interaction between man and machine is firmly anchored in TRAPO GmbH’s mission statement: to humanize workplaces and achieve production processes of consistently high quality. Cobots provide support as stationary jointed-arm robots, can be moved on rails or achieve maximum mobility – when placed on a shuttle.

See product

Pet food industry 4.0

Control, monitor. optimize: TRAPO Intelligent Management System.

See in actionPet food industry 4.0

Also in production: the best for pet supplies.

We secure and optimize production in the pet food sector: for example, by using Tim, the TRAPO Intelligent Management System. TIM makes it possible to generate, process and provide current data from plants around the clock. This allows the consistent implementation of optimizations. Enabling predictive maintenance and a digital shopping cart are also part of TIM’s expertise.

See product