24/7 Monitoring of your plant

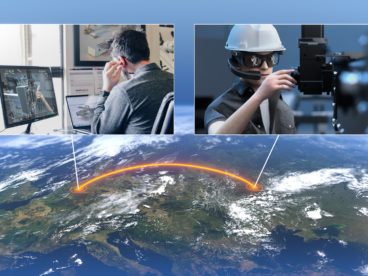

From the TRAPO control station, we keep an eye on your plants: Reduce costs and increase availability – Predictive maintenance from TRAPO.

Your advantages:

- 24/7 Monitoring of your plant*

- Proactive support from our team of specialists

*depending on the booked maintenance contract

The goal: to prevent falling performance and downtimes! We use TIM, the TRAPO Intelligent Managementsystem, as a control function at the control station.

From the control station at TRAPO, our specialists can monitor production processes and, if necessary, intervene in a controlling manner – so that customer´s plants permanently run at maximum capacity in accordance with the OEE definition for overall plant efficiency and availability. OEE defines the percentage at which the respective plant produces at a predefined speed. Deviations in the event of a drop in performance are indicated at the control station.

The service contract for predictive maintenance is fulfilled in 24/7 continuous operation. With the aim of directly identifying production losses and improving product quality, the performance of all partial and total lines is subject to TIM control.

Predictive maintenance with TIM

TIM, the TRAPO Intelligent Managementsystem, monitors equipment using scanners positioned at key sections of the line. The TRAPO control room team can use the TIM dashboard to access and read event logs of plant conditions and intervene when performance drops.

Operator or machine error? The elimination of the fault by the operating personnel on site and the cause report are also stored in TIM. These in turn form the basis for initiating specific machine optimization measures as part of predictive maintenance.