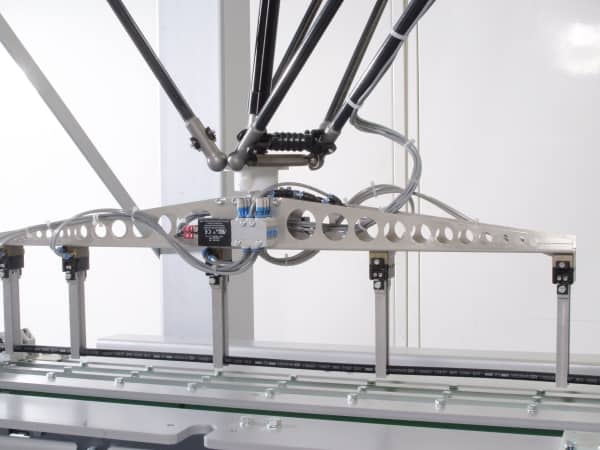

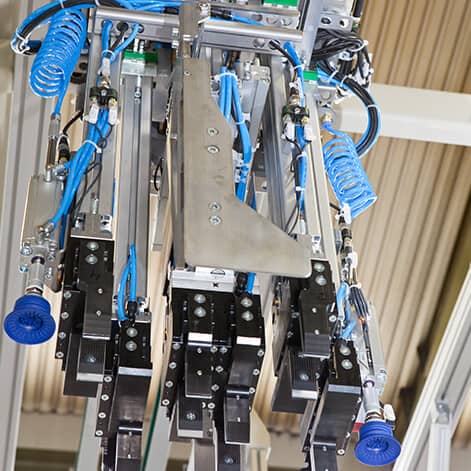

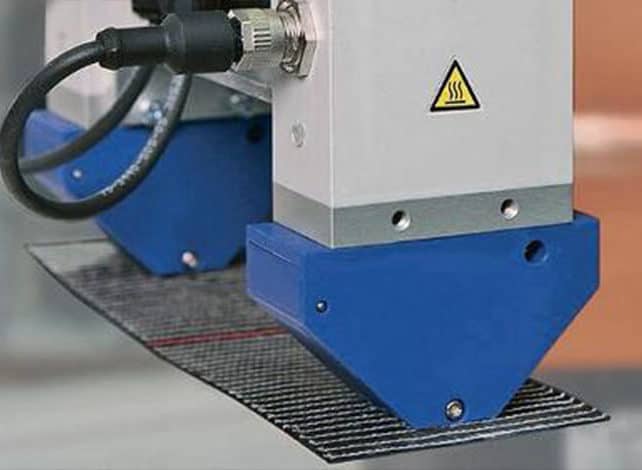

The perfect gripper for every product

The handling of objects is the central task of the robot systems. The robot grippers used are precisely adapted to the object’s properties – gripper technology is developed and tested in the TRAPO technical center.

The use of the optimal gripper developed by TRAPO is crucial when it comes to sustainably increasing performance and quality.

Key to the robot’s success is individual gripper technology

TRAPO offers maximum flexibility when it intelligently automates intralogistics tasks – in the perfect interplay of conveyor systems, robots and customized gripper technology. Product-specific gripper technology perfects the application possibilities, function and performance of a robot system.