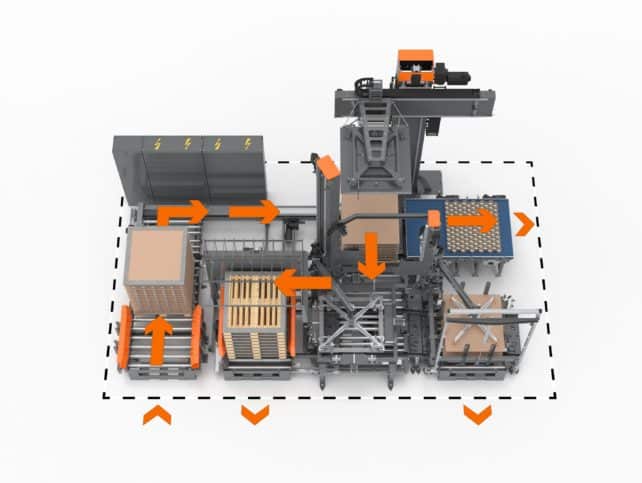

From manual operation to a fully automated depalletizing system

Until now, depalletizing has often been done manually – automating this activity enables stable, safe operations with consistently efficient production processes. A depalletizer as an integral part of an automated line works reliably in 24/7 three-shift operation.

High-speed depalletizers complete automated production lines. This is because products are not only stacked on pallets, they also have to be unpacked and removed at a constant rate. This is a time-saving intralogistics challenge that is geared to the product and the subsequent task.

High-Speed Layer Depalletizer: six layers/minute

The High-Speed Layer Depalletizer (HLDP series) combines several innovations at once: Its output of up to 90,000 empty cans per hour is impressive. Thanks to its modular design, the HLDP can also handle jars and bottles in the same way.

This innovative solution is impressive thanks to the use of a lifting column in combination with a magnetic or vacuum gripper, thus enabling the efficient depalletizing of empty food cans (tinplate/aluminum) or empty jars – at a rate of up to six layers per minute. This corresponds to around 1,500 empty cans per minute.

A safety innovation in this performance class: the depalletizer is operated completely at ground level – a second operating level by means of a platform is avoided.

Advantages

- Output: up to six 6 layers per minute

- For empty cans (tinplate, aluminum) and empty jars

- Modular system

- For empty glass: no broken glass in further production due to vacuum

- Level operation

- Pallet formats: all common formats (Euro, industrial, CHEP etc.)

- TTS Ready Shuttle connection

- Sustainably increase depalletizing performance for empty cans and jars

Technical details

HLDP with magnetic gripper

HLDP with vacuum gripper

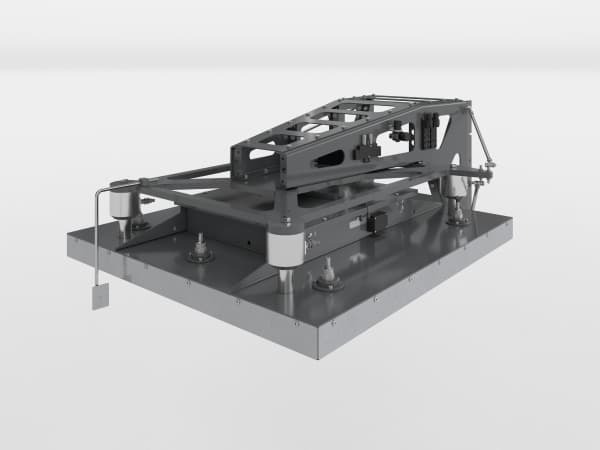

Cover frame centering at working level for exact centering of the cover frames before restacking

Highly dynamic Y-Z axis for repeatable pick-up and placement of layers

Pallet magazine for holding empty pallets up to a size of 1250mm x 1150mm incl. cover frame

Modular system

Depalletizing capacity cans: up to six layers per minute – up to 90,000 empty cans per hour

Depalletizing capacity jars: up to four layers per minute, up to 60,000 jars per hour

Power supply: 400V – 50Hz

Bottom discharge (modular system) – top discharge optional

Can be operated at ground level – no platform required

Compact footprint

Empty cans (tinplate, aluminum) and empty glasses possible

With empty glass: no broken glass in subsequent production due to vacuum

Depalletizing of tallpacks up to 3000mm on pallets up to 1250 x 1150mm

Pallet formats: all common formats (Euro, industrial, CHEP, etc.)

For the care sector in stainless steel version

Downloads

Case Studies

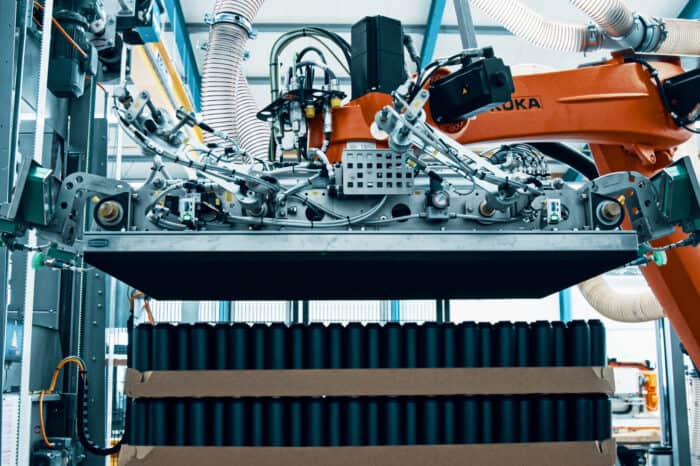

Depalletizing with articulated arm robot: safe transfer of palletized goods

TRAPO develops customized high-speed depalletizing systems – based on an articulated arm robot and the multifunctional gripper (HRS series). An efficient answer to frequently changing tray formats, changing sizes of goods to be depalletized and the demand for higher cycle times – combined in one compact machine.

We are specialists for tasks in limited production environments and for products that are difficult to handle, where powerful portal robots (HPS series) are also used.

Specialist for gripper technology

Automated depalletizing solutions grip products piece by piece, as individual or complete layers. Depending on weight and condition, layer palletizers, portal or articulated arm robots plus grippers are used. With the goal of maximum cost efficiency, TRAPO Technikum develops robot grippers analogous to the individual depalletizing task and tests them in practical applications.

Depalletizers for care areas

For depalletizing tasks in care areas, TRAPO teams manufacture all components from stainless steel fabrication in the in-house production.